Material

Tool steel.

Version

Hardened and ground (HRC 55 ±2).

Show more

Show less

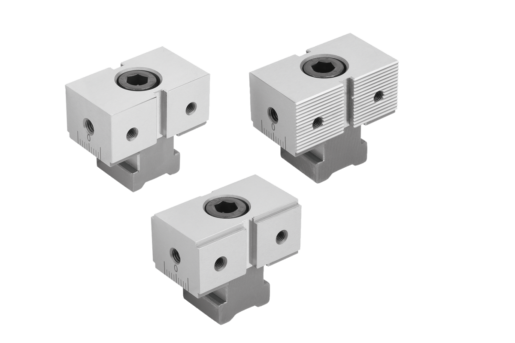

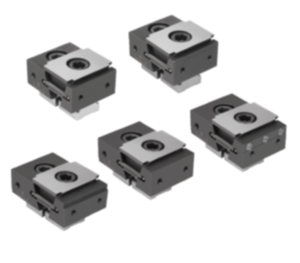

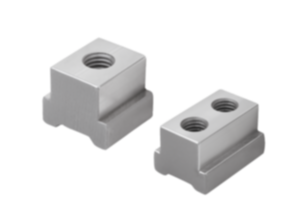

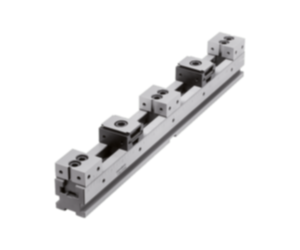

Fixed jaws ES for multi-clamping system, Form A, jaw plates smooth

from

123,85 €

plus sales tax

plus shipping costs

Fixed jaws ES for multi-clamping system, Form B, jaw plates serrated

from

147,07 €

plus sales tax

plus shipping costs

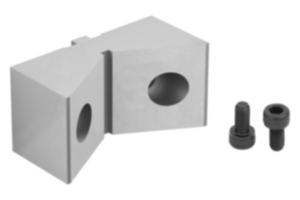

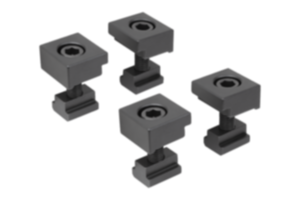

Fixed jaws ES for multi-clamping system, Form C, jaw plates offset

from

133,14 €

plus sales tax

plus shipping costs

Description

Material

Tool steel.

Version

Hardened and ground (HRC 55 ±2).

Note

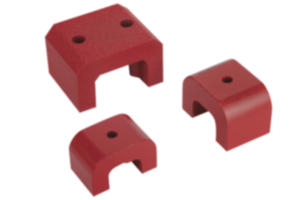

There are three different fixed jaw versions to choose from:

- Smooth version Form A for pre-machined workpieces.

- Serrated version Form B for raw parts.

- Offset jaws Form C for clamping with a small clamping edge.

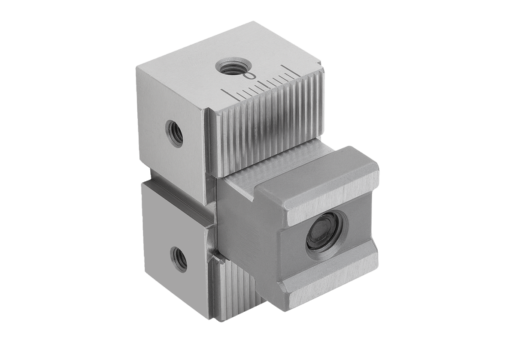

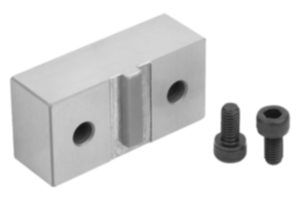

The lateral fastening holes are used to fasten workpiece end stops. The two screw-on holes on the clamping surfaces also allow seating ledges to be mounted so as to optimise the clamping depth of the workpieces.

- Smooth version Form A for pre-machined workpieces.

- Serrated version Form B for raw parts.

- Offset jaws Form C for clamping with a small clamping edge.

The lateral fastening holes are used to fasten workpiece end stops. The two screw-on holes on the clamping surfaces also allow seating ledges to be mounted so as to optimise the clamping depth of the workpieces.

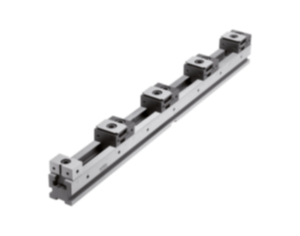

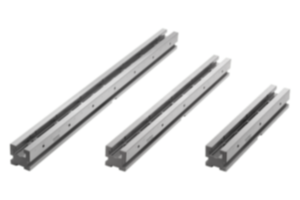

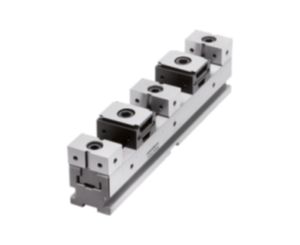

Application

The ES fixed jaws are positioned on the clamping rails according to the clamping situation. When the fastening screw is tightened, the toothing allows a form-fit connection to be created. This allows high retaining forces to be carried through the clamping elements. With its slim design, the ES fixed jaw is especially suitable for clamping processes with smaller workpieces and large batch sizes. This also means that large production batches can be processed economically.

Advantages

The lateral scale on the clamping rails and the fixed jaws allows precise positioning of the fixed stops.

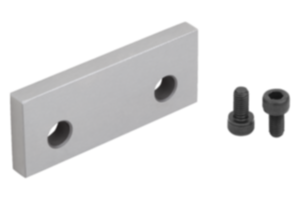

Scope of delivery

ES fixed jaw.

Fastening screw.

Slot key.

Fastening screw.

Slot key.