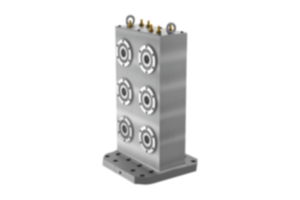

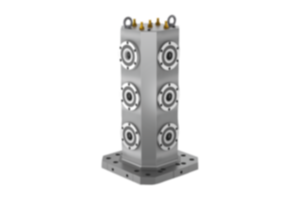

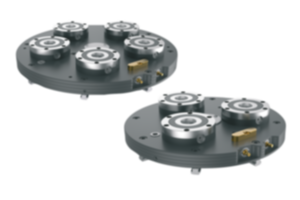

{"product":{"productId":"agid.35502","price":9426.55,"name":"UNILOCK 8x clamping stations"},"currency":"EUR"}

Material

Baseplate steel.

Clamping module case-hardening steel.

Clamping module case-hardening steel.

Version

Baseplate ground and oxidised both sides.

Clamping module contact faces hardened and ground.

Clamping module contact faces hardened and ground.

Show more

Show less

Description

Material

Baseplate steel.

Clamping module case-hardening steel.

Clamping module case-hardening steel.

Version

Baseplate ground and oxidised both sides.

Clamping module contact faces hardened and ground.

Clamping module contact faces hardened and ground.

Note

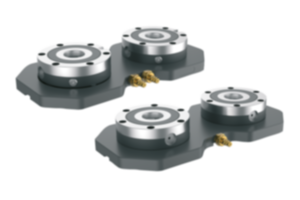

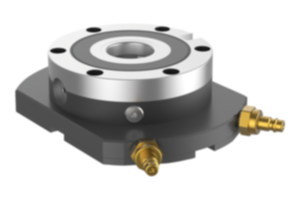

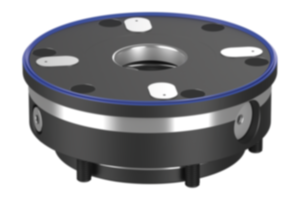

Pre-assembled clamping stations with integrated UNILOCK ESM138-C clamping modules. The clamping stations are attached to the machine table using clamping brackets or direct fasteners.

The clamping stations can be aligned using the reference bore 25H7 and reference slots 20H7.

The clamping modules are actuated using a central pneumatic port.

The high clamping forces are generated via the integrated spring package (the unit clamps while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping bolt in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping bolts may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

The clamping stations can be aligned using the reference bore 25H7 and reference slots 20H7.

The clamping modules are actuated using a central pneumatic port.

The high clamping forces are generated via the integrated spring package (the unit clamps while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping bolt in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping bolts may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

Technical Data

- Opening pressure: 6 bar, lubricated air.

- Air port: G1/8.

- Repeat accuracy ≤ 0.005 mm.

- Reference bore 25H7 and reference slots 20H7 for aligning the clamping station.

- Air port: G1/8.

- Repeat accuracy ≤ 0.005 mm.

- Reference bore 25H7 and reference slots 20H7 for aligning the clamping station.

Temperature range

+5 °C to +60 °C.

Scope of delivery

- Clamping station.

- Pneumatic plug-in port.

- Ring bolts.

- Operating instructions.

- Pneumatic plug-in port.

- Ring bolts.

- Operating instructions.

On request

Clamping station in special dimensions.

Accessory

- UNILOCK clamping brackets for UNILOCK clamping stations 42751-20.

- UNILOCK clamping bolts 42208.

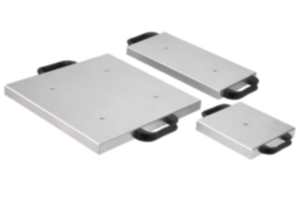

- UNILOCK interchangeable subplates for zero-point clamping system 42755.

- UNILOCK protection bolts for clamping modules 42796.

- UNILOCK covers for clamping modules 42796.

- Port strips for UNILOCK clamping stations 42797.

- UNILOCK clamping bolts 42208.

- UNILOCK interchangeable subplates for zero-point clamping system 42755.

- UNILOCK protection bolts for clamping modules 42796.

- UNILOCK covers for clamping modules 42796.

- Port strips for UNILOCK clamping stations 42797.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.