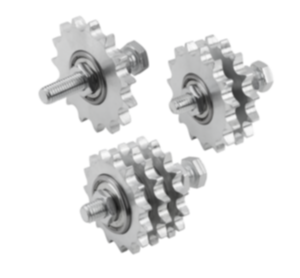

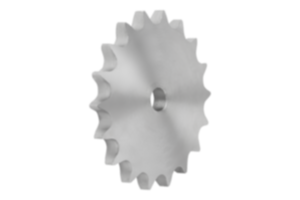

{"product":{"productId":"agid.34356","price":49.8,"name":"Chain tensioner size 0 with semicircular profile"},"currency":"EUR"}

Material

Housing thermoplastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Screws and springs stainless steel.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Screws and springs stainless steel.

Show more

Show less

Description

Material

Housing thermoplastic.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Screws and springs stainless steel.

Chain tensioner, ultra-high molecular polyethylene PE-UHMW.

Screws and springs stainless steel.

Note

Ready-to-install chain tensioner for low-noise and low-wear running of ISO 606 roller chains. The robust plastic housing offers a high level of corrosion protection.

Available in two tensioning force versions:

Version with light spring force: 58 - 32 N.

Version with high spring force: 132 - 60 N.

Simple wear control with three-colour wear indicator

green: ok

yellow: still ok

red: Insufficient spring travel (spring force below 32 or 60N). The chain tensioner needs to be readjusted. The chain must be replaced when the range of all adjustment options no longer ensures sufficient readjustment.

Available in two tensioning force versions:

Version with light spring force: 58 - 32 N.

Version with high spring force: 132 - 60 N.

Simple wear control with three-colour wear indicator

green: ok

yellow: still ok

red: Insufficient spring travel (spring force below 32 or 60N). The chain tensioner needs to be readjusted. The chain must be replaced when the range of all adjustment options no longer ensures sufficient readjustment.

Temperature range

-20 °C to +60 °C (briefly up to +80 °C).

Assembly

The ideal mounting location is directly behind the drive sprocket, so that the length of the slack side being tensioned is kept as short as possible. Several chain links should be in contact to minimise wear.

The size 0 chain tensioner is supplied in a disengaged state. Before installation, the tension core must be pressed into the housing and secured with the retaining pin supplied.

The size 0 chain tensioner is supplied in a disengaged state. Before installation, the tension core must be pressed into the housing and secured with the retaining pin supplied.

Accessory

Angle brackets 22281-90.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.