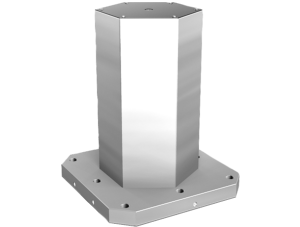

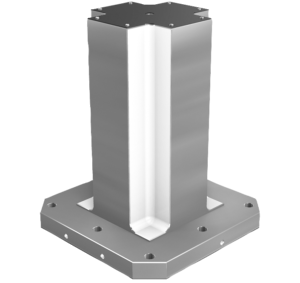

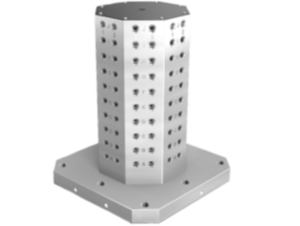

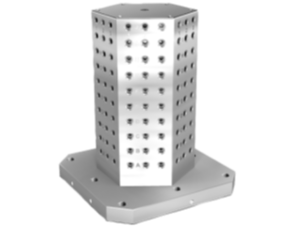

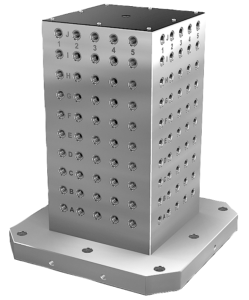

{"product":{"productId":"agid.35525","price":0,"name":"Workholding towers, grey cast iron, 4-sided with UNILOCK zero-point clamping system"},"currency":"EUR"}

Material

Workholding tower GJL 300.

Clamping module case-hardening steel.

Clamping module case-hardening steel.

Version

Workholding tower contact faces precision machined.

Clamping module contact faces hardened and ground.

Clamping module contact faces hardened and ground.

Show more

Show less

Description

Product description

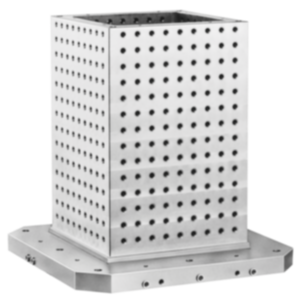

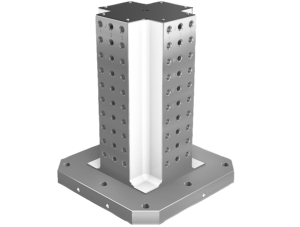

4-sided workholding tower with integrated UNILOCK clamping modules EFM 138. The integrated clamping modules enable the rapid clamping or exchange of clamping equipment and fixtures on the workholding tower. Set-up times are reduced and machine running times increased.

Material

Workholding tower GJL 300.

Clamping module case-hardening steel.

Clamping module case-hardening steel.

Version

Workholding tower contact faces precision machined.

Clamping module contact faces hardened and ground.

Clamping module contact faces hardened and ground.

Note

These 4-sided workholding towers conform to machine tables for machine tools acc. to DIN 55201 and JIS6337-1980.

The clamping modules are actuated via a central pneumatic connection.

The high clamping forces are generated via the integrated spring package (the unit clamps while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping bolt in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping bolts may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

The clamping modules are actuated via a central pneumatic connection.

The high clamping forces are generated via the integrated spring package (the unit clamps while not under pressure).

Clamping is released pneumatically.

The following clamping forces are possible with the UNILOCK clamping bolt in conjunction with M10, M12, M16 fastening screws:

- Clamping force (M10) 35,000 N/module

- Clamping force (M12) 50,000 N/module

- Clamping force (M16) 75,000 N/module

Clamping force with DIN EN ISO 4762 -12.9 cap screws

Clamping bolts may only be clamped in conjunction with a mounted interchangeable unit in the clamping module.

Temperature range

+5 °C to +60 °C.

Scope of delivery

- Workholding tower

- Transport screws.

- Operating instructions.

- Transport screws.

- Operating instructions.

Accessory

- UNILOCK clamping pin 42208.

- UNILOCK interchangeable subplates for zero-point clamping system 42755.

- UNILOCK protective bolt for clamping module 42796.

- UNILOCK protective plug for clamping module 42796.

- UNILOCK interchangeable subplates for zero-point clamping system 42755.

- UNILOCK protective bolt for clamping module 42796.

- UNILOCK protective plug for clamping module 42796.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.