{"product":{"productId":"agid.27329","price":47.92,"name":"Tension levers for rotary lever clamps, Form B blank"},"currency":"EUR"}

Description

Product description

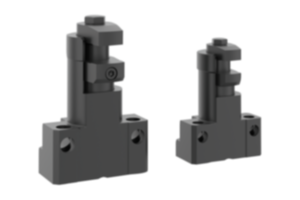

The tension lever can be used for the hydraulic rotary lever clamp 04624-20 or the pneumatic rotary lever clamp 04624-19. The ”standard” tension lever or the ”blank” tension lever can be selected. The ”standard” tension lever is finish machined and can be mounted directly. The ”blank” tension lever can be individually machined to suit. The blank lever is made from unhardened steel for easier machining. After the individual contour has been machined, the tension levers must be annealed and hardened before mounting to prevent deformation of the levers during use.

Material

Standard and blank steel.

Version

Standard hardened.

Blank not hardened.

Blank not hardened.

Note

By positioning the rotary lever clamp correctly, workpiece tolerances can be optimally compensated for despite the short clamping lever.

The clamping elements must be checked regularly for dirt and cleaned if necessary.

The effective clamping force must be calculated for every tension lever.

The optimum tension lever position is 90°.

The following hardness grade must be achieved before a ”blank” tension lever is used: Hardened depth 0.3 + 0.2 HRC 50 +/- 2.

Follow safety instruction.

The clamping elements must be checked regularly for dirt and cleaned if necessary.

The effective clamping force must be calculated for every tension lever.

The optimum tension lever position is 90°.

The following hardness grade must be achieved before a ”blank” tension lever is used: Hardened depth 0.3 + 0.2 HRC 50 +/- 2.

Follow safety instruction.

Assembly

The tension lever is attached to the piston of the rotary lever clamp and secured with a dowel pin. The tension lever is thus axially secured and secured against rotation.

On request

Other sizes and types.

Drawing reference

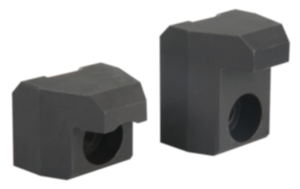

Form A: Standard

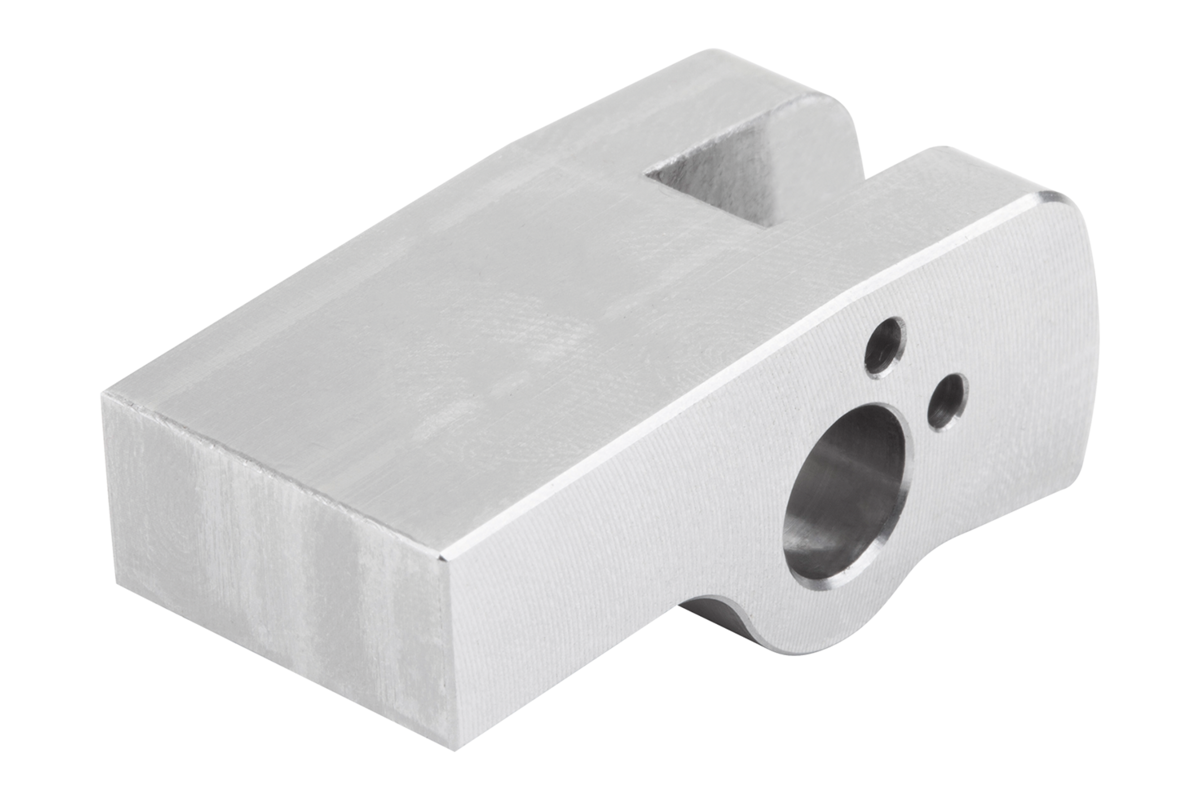

Form B: Blank

Form B: Blank

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.